Ensure a stable supply of high-reliability products in large quantities.

Flexibly respond to the diversifying needs of the electronics market and contribute to the advancement of society.

We continually look to the needs of the market and strive to quickly respond to customer demands.

Flexible response capability supported by high production technology. Power ICs, diodes, and other electronic components produced here are used in a wide range of fields, including consumer devices such as TVs, DVD players, audio equipment, communication applications (i.e. mobile phones and fax machines), medical devices, industrial equipment, computer-related sets, and automotive systems, receiving strong marks from customers and earning their trust.

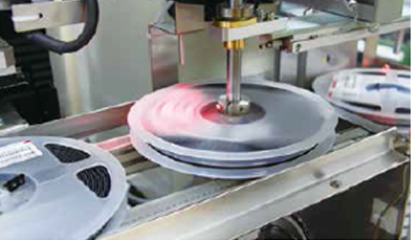

We perform assembly and packaging of diodes, LEDs, and laser diodes.Our manufacturing system leverages original technology to ensure high quality and stable supply.In particular, we have achieved top-class production volume of diodes by flexibly responding to user needs through an integrated system that carries out a variety of processes on the same line.

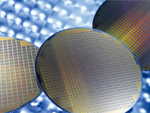

With the continuing integration and increasing performance of ICs, ROHM device and process technologies, cultivated over many years, have become the driving force that allowed ROHM to gain a distinct competitive advantage in the global market. ROHM Wako is responsible for the wafer process of power ICs, one of ROHM's flagship products. We also carry out wafer fabrication for our high reliability switching and Schottky barrier diodes which enjoy a large market share and have been adopted in applications of all types.

Please visit ROHM's website for more information

Utilizing over a half century of expertise in warehouse management and information systems allows us to consistently provide high-level logistics services that leverage new technologies and ideas.

We promote warehouse automation to deliver stable, high quality logistics services. And are working to build a new era of logistics systems by developing fully automated receiving and picking robots linked to our vertically automated warehouse together with automated shipping and packing machines tailored to individual customer logistics requirements.

By phasing out paper-based processes and establishing a flexible data-based work system, we are able to respond to the evolving needs of our customers. All conventional work slips have been digitized, ensuring that the latest information is readily available throughout the workflow process in a timely manner.

We support the globalization of logistics services by deploying logistics systems and automation equipment to the ROHM Group's overseas logistics bases (i.e. Europe, the US, Asia) while supporting improvements based on the situation at each site.